Mga spotlight

Facility Engineer, Manufacturing Engineer, Plant Engineer, Process Engineer, Process Improvement Engineer

Kung ang isang produkto ay hindi gawa sa kamay, malamang na ginawa ito sa isang pabrika sa isang lugar. Ang paggawa ng mga kalakal ay isang napakasalimuot ngunit maayos na proseso na kinasasangkutan ng ilang manggagawa. Kabilang sa mga pinaka-kritikal na empleyado ng pabrika ay ang Manufacturing Engineers. Ito ang mga dalubhasang maraming nalalaman na tumitiyak na tumatakbo nang maayos at ligtas ang mga linya ng produksyon upang magawa ang mga produkto nang kasing-episyente hangga't maaari.

Maaaring sila ang namamahala sa isang malawak na hanay ng mga sistema ng pagmamanupaktura gaya ng "mga network ng kompyuter, mga robot, mga tool sa makina, at kagamitan sa paghawak ng mga materyales." Ang kaligtasan sa lugar ng trabaho ay pangunahing alalahanin ng mga Manufacturing Engineer habang naghahanap sila ng mga paraan upang maputol ang mga masayang aspeto ng mga proseso ng produksyon, isinasaalang-alang kung gaano karaming mga manggagawa ang kailangan para sa isang gawain, kung anong mga hakbang ang kanilang gagawin, kung aling mga teknolohiya ang kakailanganin nila, at magkano lahat ng gastos. Maaari nilang pangasiwaan ang mga proseso ng pagtiyak ng kalidad upang matiyak na ang mga produkto ay nakakatugon sa mga detalye at handa nang ipadala sa mga tindahan o bodega upang maghintay ng pagbili.

- Pakikipagtulungan sa mga komersyal at pang-industriya na taga-disenyo upang mapabuti ang mga produkto

- Paggawa sa iba't ibang mga koponan patungo sa isang karaniwang layunin

- Pagtulong na panatilihing ligtas ang mga empleyado mula sa mga panganib sa lugar ng trabaho

- Pag-maximize ng kahusayan sa produksyon upang mapanatiling mababa ang gastos ng mga employer

- Pagbuo ng mga kapana-panabik na bagong konsepto at produkto upang i-market sa mga mamimili

- Ang paggawa ng mga ideya sa mga nasasalat na kalakal

- Pagpapabuti ng mga teknolohiyang makakapagsagawa ng mga mapanganib na gawain upang hindi na kailanganin ng mga tao

Oras ng trabaho

- Karamihan sa mga Manufacturing Engineer ay nagtatrabaho nang full-time, na may posibilidad na mag-overtime sa panahon ng abalang panahon, o kapag ang produksyon ay nasa likod ng iskedyul o ang mga order ay lumampas sa mga projection.

- Mga Karaniwang Tungkulin

- Makipagkita sa mga customer para talakayin ang mga detalye para sa kanilang mga gustong produkto

- Makipag-usap sa mga vendor at pamamahala tungkol sa katayuan ng mga kakayahan, timetable, limitasyon, at posibleng solusyon sa mga isyu

- Tukuyin ang mga tamang tool, makina, kagamitan, at proseso para gumawa ng mga partikular na bahagi o produkto batay sa mga detalye

- Humanap ng mga paraan upang bawasan o alisin ang mga mapaminsalang gawi at materyales

- Suriin ang mga iskedyul at daloy ng trabaho upang matiyak na ang tamang bilang ng mga manggagawa ay itinalaga

- Gumamit ng mga sistema ng kontrol sa pamamahala upang ayusin ang mga pagsisikap ng pangkat

- Magtatag ng mga protocol ng pagtiyak ng kalidad upang matiyak na ang mga produkto ay ginawa sa mga pamantayan

- Patuloy na tasahin ang bilis ng produksyon at maghanap ng mga paraan upang mapabuti ang kahusayan at bawasan ang mga gastos gamit ang mga prinsipyo sa pagmamanupaktura

- Makipagtulungan sa mga production team para panatilihin ang mga bagay sa oras, sa target (at on-budget)

- Suriin ang mga daloy ng trabaho upang hanapin (at pagaanin) ang mga potensyal na problema gaya ng mga bottleneck

- Gumawa ng mga backup na plano upang malutas ang mga hindi inaasahang problema na maaaring magdulot ng mga pagkaantala o paghinto sa trabaho

- Subukan at i-troubleshoot ang mga disenyo, materyales, at proseso

- Mag-alok ng teknikal na tulong o pagsasanay kung kinakailangan

- Regular na mag-check-in kasama ang mga tauhan upang makita kung paano umuusad ang mga proyekto. Pangasiwaan, kung kinakailangan

- Siyasatin ang mga ugat na sanhi ng mga pagkabigo sa produksyon at magmungkahi ng mga pag-aayos o pagsasaayos

- Bumuo ng mga ulat sa pagganap ng pagmamanupaktura

- Suriin ang mga salik sa pananalapi na nauugnay sa mga napapanatiling proseso at mag-alok ng mga mungkahi sa pamamahala

- Tiyakin ang napapanahong paghahatid ng mga kalakal sa mga kliyente habang pinapanatili ang cost-effective na mga kasanayan sa transportasyon

Karagdagang Pananagutan

- Idisenyo ang workspace at mga layout ng kagamitan at pangasiwaan ang mga pag-install

- Bumili ng kagamitan, bahagi, at iba't ibang materyales, kung kinakailangan

- Sumulat ng dokumentasyon para sa iba't ibang proseso ng trabaho

- Manatiling up-to-date sa mga pagpapabuti sa proseso ng paggawa at pagpupulong

- Basahin ang tungkol sa mga uso at teknolohikal na pagsulong sa tooling at kagamitan at isama ang mga ito kapag posible

- Tiyakin ang pagsunod sa mga code at pamantayan ng estado, pederal, at internasyonal

- Makilahok sa patuloy na edukasyon at mga kaganapan sa organisasyong propesyonal

Soft Skills

- Kakayahang magkonsepto

- Kakayahang mapadali ang pakikipagtulungan sa pagitan ng mga koponan

- Adaptive na istilo

- Analitikal

- May kamalayan sa badyet

- Kalmado sa ilalim ng presyon

- Nakatuon sa pagsunod at kaligtasan

- Konsentrasyon at pokus

- Mahusay na mga kasanayan sa pamamahala ng talaan

- Inisyatiba

- Makabago

- Imbestigasyon

- Pamumuno

- Organisado

- pasensya

- Pagtugon sa suliranin

- Makatotohanan

- Malakas na tao at mga kasanayan sa komunikasyon

- Pagtutulungan ng magkakasama

- Pamamahala ng oras

Teknikal na kasanayan

- Computer-aided design (CAD) na mga tool tulad ng Autodesk AutoCAD

- Kaalaman sa mga proseso ng linya ng pagpupulong

- Kaalaman sa Solidworks

- Lean manufacturing

- Pagpapabuti ng proseso

- Mga prinsipyo ng katiyakan ng kalidad

- Pagsusuri ng sanhi ng ugat

- Anim na Sigma

- Mga taktika sa pag-troubleshoot

- Pag-unawa sa mechanical engineering

- Industriya ng sasakyan; paggawa ng mga kagamitan sa transportasyon

- Mga gumagawa ng computer/electronic na produkto

- Mga kumpanya sa paggawa

- Mga ahensya ng militar at pamahalaan

Pinapanatili ng mga Manufacturing Engineer ang produksyon ng pabrika nang maayos, ngunit mayroong isang toneladang trabaho at pagpaplano upang makarating sa puntong iyon. Mula sa pagpili ng mga manggagawang may tamang kasanayan at pagpili ng pinakamahuhusay na kasangkapan, kagamitan, at makinarya hanggang sa paglalatag ng mga workspace at pagtatatag ng mga pamamaraan, ang mga Manufacturing Engineer ay tiyak na may trabaho para sa kanila!

Ang mga kumpanya ay lubos na umaasa sa kanilang mga talento upang panatilihing dumadaloy ang produksyon, bumaba ang gastos, at ligtas ang mga manggagawa. Ang isang masamang desisyon o pangangasiwa ay maaaring magtapon ng isang kilalang unggoy na wrench sa mga gawa, na magdulot ng mga mamahaling problema sa pagmamanupaktura mula sa mga may sira na produkto hanggang sa mga pagpapabalik sa kaligtasan at kabuuang pagpapahinto sa trabaho. Kung ang isang seryosong hindi ligtas na produkto ay tumama sa merkado, maaari nitong masira ang reputasyon ng kumpanya at magdulot ng pagkasira ng pananalapi para sa hinaharap nito. Sa ibang pagkakataon, ang isang produkto ay malamang na dapat ay nixed sa panahon ng konsepto phase, tulad ng Cheetos 'nakapahamak lip balm produkto nabigo.

Ang pananaw sa trabaho ay malakas para sa Mga Manufacturing Engineer, sa bahagi dahil sa mga pagtitipid sa gastos na dinadala nila sa talahanayan. Ang isang pangunahing bahagi ng trabaho ay nananatili sa tuktok ng mga uso at mga pagbabago, kung saan mayroong ilang mga araw na ito.

Matagal nang naging pangunahing layunin ng maraming pabrika ang automation at nagiging laganap at mas madaling gamitin. Ang mga mobile at collaborative na robot ay inihanda din upang baguhin ang landscape ng pagmamanupaktura, na nagdadala ng kapana-panabik na mga bagong kakayahan upang dalhin. Samantala, ang kuwentong Internet of Things ay patuloy na umuusad, na nagbibigay ng kapangyarihan sa mga kumpanya na mangalap ng mahalagang data na magagamit nila upang i-optimize ang mga proseso.

Pinarangalan bilang Ika-apat na Rebolusyong Pang-industriya, ang Industry 4.0 ay nabubuhay hanggang sa ang hype na may ilang mga inisyatiba na hinimok ng "high-speed mobile Internet, AI at automation, ang paggamit ng malaking data analytics, at cloud technology." Kasama sa mga karagdagang trend ang kumakalat na paggamit ng Enterprise Resource Planning, na halos hindi na bago ngunit mas madaling i-deploy ngayon salamat sa cloud-based na SaaS.

Ang mga Manufacturing Engineer ay napaka pamamaraan at nakatuon sa proseso. Maaaring nasiyahan sila sa paggawa ng mga maselan na aktibidad na nangangailangan ng pagsunod sa maraming hakbang sa isang tiyak na pagkakasunud-sunod, tulad ng paggawa ng masalimuot na mga set ng LEGO. Masigasig silang alisin ang mga inefficiencies, at maaaring nakahanap sila ng mga paraan upang magawa ang kanilang mga gawain (o ang kanilang takdang-aralin) nang mas mabilis kaysa sa maaaring gawin ng iba. Tulad ng karamihan sa mga inhinyero, kadalasang gustong-gusto nilang alamin kung paano gawing kongkretong katotohanan ang mga abstract na ideya sa pamamagitan ng kaunting malikhaing pag-iisip at pag-iisip.

Dahil madalas silang nahuhulog sa makabagong teknolohiya kabilang ang AI at robotics, maaaring sila ay masugid na tagahanga ng science fiction noong bata pa sila. At dahil kailangan nilang pangasiwaan ang gawain ng maraming tao at grupo, ang mga Manufacturing Engineer sa pangkalahatan ay may mahusay na nabuong mga soft skill na malamang na nilinang sa mga ekstrakurikular na aktibidad sa paaralan o mula lamang sa paglaki sa isang malaking pamilya.

- 70% ng mga Manufacturing Engineer ay mayroong bachelor's degree; 16% ang may hawak na master's. Maraming mga programa sa unibersidad ang nagtatampok ng dalawahang bachelor's/master's degree track na tumatagal ng ~5 taon

- Karamihan sa major sa industrial engineering, manufacturing engineering, o mechanical engineering

- Ang mga programa sa engineering ay dapat na akreditado ng ABET

- Madalas kailangan ng master para magturo o magtrabaho sa R&D

- Ang mga internship, co-op, at iba pang praktikal na karanasan sa trabaho ay pinahahalagahan ng mga employer

- Hindi kailangan ng lisensya para makapagsimula, ngunit ang lisensya ng Professional Engineering (PE) ay maaaring humantong sa mga pagkakataon sa pag-promote

- Ang PE ay dapat pumasa sa dalawang pagsusulit:

- Fundamentals of Engineering (FE)

- Principles and Practice of Engineering (PE) na pagsusulit

- Ang PE ay dapat pumasa sa dalawang pagsusulit:

- Mayroong ilang mga opsyonal na certification na dapat isaalang-alang, kabilang ang:

- American Society for Quality - Certified Six Sigma Yellow Belt

- American Society of Mechanical Engineers International - Geometric Dimensioning & Tolerancing Professional - Technologist

- Autodesk -

- Autodesk Moldflow Insight Professional Certification

- Autodesk Moldflow Insight Associate Certification

- International Association of Six Sigma Certification - iba't ibang kulay na sinturon

- Packaging Machinery Manufacturing Institute - Mechatronics Certification Test - Mga Kontrol sa Motor at Motor

- SAP America- Certified Application Associate - SAP S/4HANA Cloud (pampubliko) - Pagpapatupad ng Manufacturing

- Society for Maintenance & Reliability Professionals - Certified Maintenance & Reliability

- Lipunan para sa Mga Inhinyero sa Paggawa -

- Lean Silver Certification

- Sertipikasyon ng Six Sigma Green Belt

- Sertipikadong Manufacturing Engineer

- Six Sigma Master Black Belt Certification

- Lean Gold Certification

- Ang mga programa ay dapat na akreditado ng ABET, na isang kinakailangan para sa paglilisensya ng PE sa ibang pagkakataon

- Maghanap ng mga scholarship at STEM pathway para makatipid ng oras at pera

- Isaalang-alang ang mga parangal at tagumpay ng mga guro ng programa. Kabilang sa mga prestihiyosong parangal ang: mga parangal sa pagtuturo, mga parangal at pagkilala sa IEEE at National Science Foundation, Fulbright Fellowships, pinakamahusay na mga papeles, at mga kilalang lecturer

- Tingnan ang kanilang mga pasilidad (lalo na kung nagpaplano kang dumalo nang personal). Ang mga programang mahusay na pinondohan ay magkakaroon ng pinakamoderno, makabagong mga lugar ng pananaliksik

- Maghanap ng mga kaakibat na sentro at institusyon. Karamihan sa mga malalaking programa ay nakikipagtulungan sa mga panlabas na kasosyo na maaaring makabuluhang dagdagan ang iyong karanasan sa pag-aaral

- Palaging tingnan kung anong mga benepisyo o mapagkukunan ang inaalok ng mga paaralan sa kanilang mga nagtapos. Tumutulong ba sila sa paghahanda ng panayam o may malapit na kaugnayan sa lokal na industriya? Nag-aalok ba ang alumni network ng career-enhancing mentorship at networking?

- Magbabayad upang makapagsimula sa kolehiyo sa pamamagitan ng pagkuha ng mga prep class sa high school, gaya ng matematika, pisika, engineering, at teknolohiya. Ang malakas na kasanayan sa Ingles at teknikal na pagsulat ay magbabayad din sa ibang pagkakataon

- Magpasya kung anong uri ng pagmamanupaktura ang gusto mong makasali, gaya ng automotive, komersyal na mga produkto, computer, atbp.

- Alamin ang lahat ng iyong makakaya tungkol sa larangan ng karera bago mag-sign up para sa mga klase. Gumawa ng ilang maagang reconnaissance sa pamamagitan ng pagbabasa ng mga paglalarawan ng trabaho na naka-post sa mga portal ng trabaho

- Gumawa ng listahan ng mga organisasyong pinapangarap mong magtrabaho, at maaaring makipag-ugnayan sa mga kasalukuyang empleyado upang piliin ang kanilang mga utak

- Kabilang sa mga pangunahing kumpanya sa pagmamanupaktura na nakabase sa US ang Ford, General Motors, Dell, Johnson & Johnson, General Electric, Intel, IBM, Procter & Gamble, PepsiCo, Lockheed Martin, Boeing, Hewlett-Packard, at Raytheon

- Kumuha ng praktikal na karanasan sa pamamagitan ng mga internship o apprenticeship

- Huwag pabayaan ang mga soft skills. Ang mga inhinyero ay dapat na "mga tao" din!

- Magboluntaryong maglingkod sa mga komite ng paaralan o tumulong sa mga ekstrakurikular na aktibidad, na may pagtuon sa mga tungkuling nag-aalok ng mga karanasan sa pamumuno at pamamahala

- Magsuklay sa aming listahan sa ibaba ng Mga Inirerekomendang Website upang makahanap ng mga propesyonal na grupong sasalihan

- Maging aktibong kalahok sa mga engineering club ng iyong paaralan

- Magtanong sa isang batikang Manufacturing Engineer kung gagawa sila ng isang panayam na nagbibigay-kaalaman sa iyo

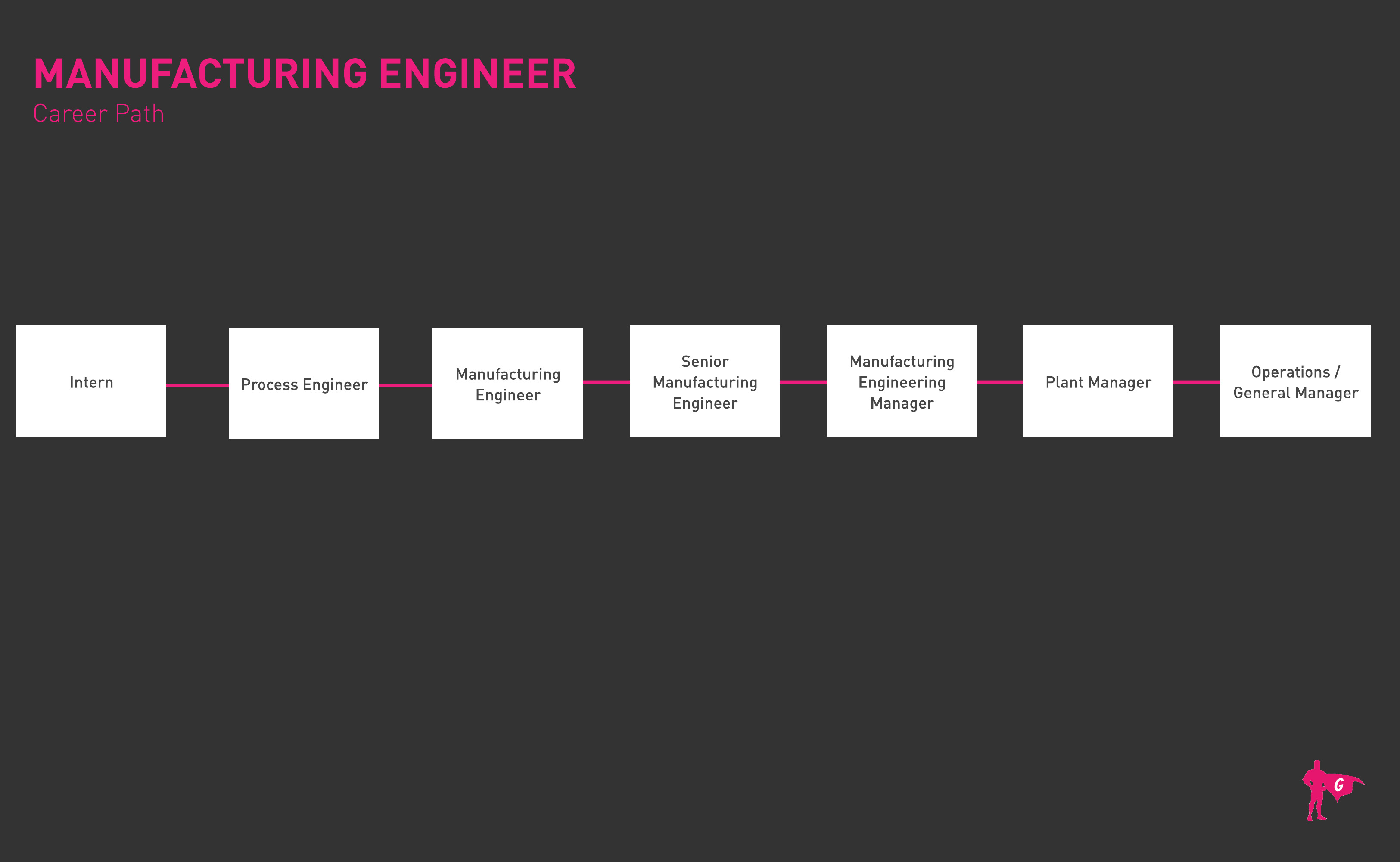

- Ang mga nagtapos sa kolehiyo ay kailangang mag-apply sa entry-level na mga posisyon ng Manufacturing Engineer sa mga pabrika o bodega

- Ang pagkakaroon ng isa o dalawang taon ng may-katuturang karanasan sa trabaho ay makakatulong na gawing mas mapagkumpitensya kapag nag-aaplay

- Ang mga internship ay maaaring magandang pagkakataon upang makakuha ng praktikal na karanasan, at kung minsan ay humahantong sila sa mga full-time na trabaho!

- Maging flexible tungkol sa mga oras na maaari kang magtrabaho. Maaaring ma-tag ang mga bagong hire para sa tungkulin sa gabi o katapusan ng linggo

- Mag-sign up para sa mga notification sa mga portal ng trabaho tulad ng Indeed, SimplyHired, Monster, USAJobs, ZipRecruiter, LinkedIn, Velvet Jobs, at Glassdoor

- Tanungin ang lahat sa iyong network tungkol sa mga pagbubukas. Bawat PayScale, 85% ng mga trabaho ay matatagpuan sa pamamagitan ng networking!

- Humingi ng tulong sa career center ng iyong paaralan sa pagsulat ng resume, mock interview, at pakikipag-ugnayan sa mga recruiter

- Gawin ang iyong araling-bahay sa kumpanya at iangkop ang iyong resume sa partikular na pag-post ng trabaho, sa bawat oras

- Suriin ang mga template ng resume ng Manufacturing Engineer at mga karaniwang tanong sa panayam

- Tandaan na ang mga maliliit na kumpanya ay maaaring hindi magkaroon ng mga pagkakataon sa pag-unlad na maaaring gusto mo sa ibang pagkakataon, ngunit malamang na mas malamang na kumuha sila ng isang taong may mas kaunting karanasan.

- Maging isang dalubhasa sa paksa na nagsasagawa ng mga bagay-bagay, nagpapakinis ng mga proseso, nagbabawas ng mga gastos, at nagpapanatiling produktibo at ligtas ang mga manggagawa

- I-mapa ang iyong mga pangmatagalang layunin, magtatag ng mga milestone, at istratehiya kung paano mo makakamit ang mga ito

- Kapag mayroon kang sapat na karanasan sa trabaho, patumbahin ang isang propesyonal na sertipikasyon

- Kunin ang iyong lisensyang Professional Engineer upang ipakita ang iyong pangako sa kahusayan at pagnanais na harapin ang mas malalaking responsibilidad

- Makipag-usap nang tapat sa iyong tagapag-empleyo upang talakayin ang iyong mga layunin sa karera. Magtanong tungkol sa mga pagkakataon sa pag-promote kapag ang oras ay tama, at alalahanin ang oras at pagsisikap na kanilang inilaan sa iyo

- Subukang manatiling flexible nang hindi nakompromiso ang iyong mga pangarap. Kung posible ang isang in-house na promosyon sa malapit na hinaharap, maaaring mas mabuting maghintay kaysa tumalon sa trabaho para sa ibang kumpanya

- Magpasya kung ano ang mas mahalaga sa iyo — isang mas mataas na rate ng suweldo o isang mas personal na kapaki-pakinabang na trabaho? Kung mahahanap mo ang pareho, mas mabuti iyon!

- Kung nagtatrabaho ka sa isang mas maliit na kumpanya, maaaring permanenteng limitado ang iyong mga opsyon maliban kung mag-apply ka sa ibang lugar, ngunit kung hindi ka makakakuha ng promosyon, humiling man lang ng pagtaas at bigyang-katwiran ang iyong mga dahilan

Mga website

- Accreditation Board para sa Engineering at Teknolohiya

- American Society for Engineering Education

- American Society of Mechanical Engineers

- Sentro ng Serbisyo sa Edukasyon sa Inhinyero

- Institute of Industrial & Systems Engineers

- National Council of Examiners for Engineering and Surveying

- Pambansang Lipunan ng mga Propesyonal na Inhinyero

- Lipunan ng Mga Inhinyero sa Paggawa

- Lipunan ng mga Babaeng Inhinyero

- Samahan ng Mag-aaral sa Teknolohiya

Mga libro

- Fundamentals of Modern Manufacturing: Materials, Processes and Systems , ni Mikell P. Groover

- Manufacturing Engineering & Technology , nina Serope Kalpakjian at Steven Schmid

- Manufacturing Engineering Handbook , ni Hwaiyu Geng

Mayroong ilang mga field at subfield ng engineering, at daan-daang mga career path na mapagpipilian. Kung ang Manufacturing Engineering ay hindi katulad ng iyong tasa ng tsaa, ang ilang mga alternatibong trabahong nauugnay sa engineering ay kinabibilangan ng:

- Mga Inhinyero ng Aerospace

- Mga Tagapamahala ng Arkitektural at Engineering

- Mga Biomedical Engineer

- Mga Computer Hardware Engineer

- Electrical at Electronics Engineering Technicians

- Mga Logistics Engineer

- Mga Inhinyero ng Mekanikal

- Mga Administrator ng Network at Computer Systems

- Mga Inhinyero ng Photonics

- Mga Sales Engineer

Para sa mga hindi naman gustong ituloy ang isang engineering path, ang mga trabaho na nauugnay din sa Manufacturing Engineering ay kinabibilangan ng:

- Mga Estimator ng Gastos

- Mga Tagapamahala ng Pang-industriya na Produksyon

- Logisticians

- Mga Analyst ng Pamamahala

- Mga Espesyalista at Technician sa Kalusugan at Kaligtasan sa Trabaho

- Mga Inspektor ng Quality Control

Newsfeed

Mga Tampok na Trabaho

Mga Online na Kurso at Tool